Implementing new software systems such as ERP, CRM, or PIM is always a major undertaking. Organizations often face the challenge of managing the requirements analysis, software selection, and subsequent system implementation with existing staff capacity. What is clear, however, is that the introduction of such new solutions is associated with far-reaching opportunities. This customer story is no exception.

Project review with Steinberg Media Technologies GmbH

As a partner for holistic digital transformation, we see every day which steps are relevant for the implementation of different systems, which challenges can arise, and where the path is paved for new, more efficient approaches.

In this project review with Steinberg, we reflect on how a Product Information Management (PIM) system has a lasting impact on the digital value chain. We show what happens after the implementation of the system and what ideas can also be derived from the use of a PIM system.We are particularly interested in how well the system is integrated into Steinberg's overall architecture and how sustainably the introduced data models and workflows are used.

The starting point - Manual product maintenance without a single source of truth

Founded in 1984 as a software start-up in Hamburg, Germany, Steinberg Media Technologies is now one of the world's largest manufacturers of audio software and hardware. Steinberg's products are packed with features that require explanation to customers. Centralized information management is not only helpful, it is essential. The need for a single source of truth for product data became apparent.

The internationalization of the business model has also increased Steinberg's requirements for the distribution of product information. For example, the user experience with a Steinberg product now often begins with a search on the Internet.Throughout the product lifecycle, the customer is presented with a variety of information. For Steinberg, it is particularly important that the quality and timeliness of the information is precisely tailored to the customer's needs and is consistent at all times.

Prior to the introduction of a PIM system, Steinberg's product data was primarily maintained in the website's content management system (CMS). Not only did this require a huge amount of manual effort to create each new product, but it also meant that the product data could only be used for the website.

Centralized management of product information was not possible. This approach also did not allow for the distribution and use of the information for other channels and platforms. Instead, all information about the product had to be retrieved, copied, prepared, and distributed separately for each sales channel (e.g., newsletter, reseller). Reason enough to decide to implement a PIM system.

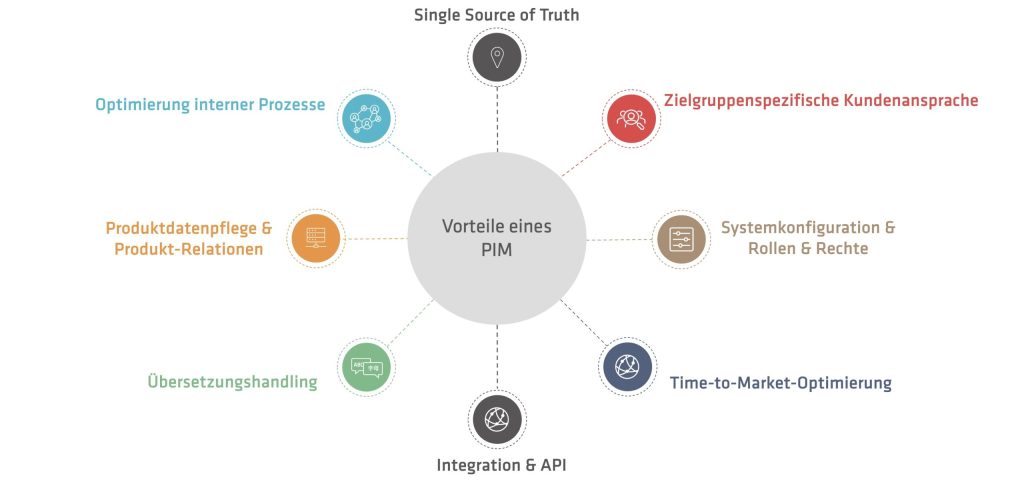

But what is behind PIM and what can a PIM system really do?

A Product Information Management (PIM) system is an enabler on many levels. On the one hand, the system allows for centralized product maintenance, which greatly simplifies the work of product managers.It also allows companies to create a single source of trust-a superior source for comprehensive product data and large data sets.

In addition to product data such as descriptions, features, or dimensions, you can also store direct links to other products, accessories, spare parts, or even media such as images, instructional videos, or downloads.

This multi-layered classification of products provides systematic access to all relevant product information and makes it directly usable across multiple channels and platforms. In the PIM, roles and rights, access to translations and evaluations of product data ("data governance") can be individually controlled.

Steinberg takes the path to single source of trust with PIM

In order to benefit from the advantages of a PIM system, Steinberg first decided to work with Xtentio to analyze the company's Information Supply Chain (ISCM) and make recommendations for action. Looking at all the processes, systems, and stakeholders involved in product data helps determine what actions are needed to best integrate IT systems and the data and interfaces they represent with processes and people.

The analysis made it clear that Steinberg's product landscape needed to be mapped in advance in a new, uniform and global product data model in order to make the scope of the underlying data and its relationships visible. Based on this model and other functional requirements, the evaluation of various software solutions began. Xtentio's software selection methodology also ensured that the best functional and economic solution was found - 100% independent of software vendors. In particular, Xtentio's structured approach to building the foundation to reach the big goal step by step was highly appreciated by all project participants.For Steinberg, it was crucial to think outside the product box and approach new requirements systematically and product-agnostically.

Even after the selection of the appropriate software solution, the cooperation with Xtentio continued during the actual implementation of the PIM system. With an external partner at their side, Steinberg were able to delegate individual tasks, maintain focus, and work out plans meticulously and profitably, free from previous structures.

In addition, the neutral viewpoint meant that all relevant parties across the company were involved, and responsibilities could be clearly defined across departments. Xtentio took over the project management and was also the technical sparring partner for Steinberg and the software integrator during the implementation.

"The introduction of the PIM and ultimately the product data model has been one of the central decisions and actions of the last few years for me personally and from a company perspective. The whole thing has such great value that you can really only underestimate it." Daniel Röper, Director Digital Unit at Steinberg

Project completion paves the way for new opportunities

Today, Steinberg maps products hierarchically in the PIM system - for example, across families and generations, to which various descriptions and media are assigned in the form of attributes. The system displays a wide range of information directly on the product. For example, the Product Life Cycle Schedule - a schedule that provides information about product updates and enhancements. Configuration data for different systems, item-related descriptions of product benefits and features, and even product comparison options at the overview level are now easy to implement. Of course, a direct link between the system and the website was also implemented, so that Steinberg's customers worldwide can benefit from up-to-date and consistent product information. Today, the PIM system and the product data model it stores are the basis for many other use cases, such as analyzing and evaluating store sales and license management.

"I'm impressed with how sustainable this project has been and that even after eight years, the foundation we laid back then is still the basis for their business model." Marco Hoff, Senior Consultant at Xtentio

Due to its comprehensive benefits, the PIM now plays a very important role in Steinberg's system architecture. Today, the basic structure created helps with a variety of projects, such as categorizing business intelligence data. It's not for nothing that Steinberg calls the Product Data Model the "gift that keeps on giving".

The pieces of the puzzle, previously scattered throughout the company, are now in place. The next step for Steinberg is to further develop its business and product strategy. They also want to better understand how customers behave in order to improve targeting across the organization. The e-commerce business is a particular focus here and offers great potential. The PIM system provides a fundamental foundation for this and will continue to be a key enabler in the future.

Video: Why a PIM System is the central element of the data supply chain

PIM expert and Xtentio CEO Thomas Lucas-Nülle explains in the three-part B2B Experts Talk with Michael Haufler why a Product Information Management system is worthwhile and how manufacturers and retailers can benefit from classification systems such as ETIM.